The Formation and Prevention of Black Pad and Phosphorus-Rich Layers

In our daily SMT soldering operations, we often find that ENIG surface-treated boards are prone to two fatal problems: nickel corrosion and phosphorus-rich layers. Once such problems occur, they often cause a lot of batch solder joint reliability problems. Because these two types of problems are very concealed, the current reproduction is generally not easy to detect. Once found, most of them are too late. The damage and losses have already been caused and may not be able to make up.

There are basically two main reasons why ENIG forms black pad: phosphorus-rich and nickel oxide.

Phosphorus comes from the electroless nickel coating. In the subsequent gold and chemical nickel replacement process, because the phosphorus does not react, it will stay between the gold layer and the nickel layer to form a phosphorus-rich layer, and finally lead to the embrittlement results.

Nickel oxide is basically composed of the complex NixOy chemical formula (x and y are numbers). The fundamental reason is that the nickel surface is subjected to excessive oxidation during the gold immersion replacement reaction, plus the very large gold atoms Irregular deposition results in coarse and loose porous grain arrangements. In other words, the gold layer failed to completely cover the bottom nickel layer, allowing the nickel layer to be exposed to the air and contact with oxygen to continue to oxidize over time, so nickel rust gradually formed under the gold layer, which eventually caused welding Hinder.

Because most of the solder, such as SAC305, SAC3005, SnBi, SnBiAg and other components are basically based on tin (Sn), when the circuit board is heated by the reflow furnace, Sn will form Ni3Sn4 with ENIG’s nickel (Ni) 4 IMC (common compound), if the nickel layer is oxidized, it will be difficult to produce the ideal IMC (intermetallic compound)), even if it can be barely generated, the IMC is also intermittently uneven, which will cause a decrease in welding strength, just like a piece of brick walls covered with cement, the cement between the brick walls and the brick walls is just like IMC. If the cement is not applied to some places, the strength of the walls will become weak.

Two potential problems of ENIG pad and its prevention

Basic ENIG process

One of the biggest advantages of ENIG surface treatment circuit boards is that the manufacturing process is simple. In principle, only two chemical potions (electroless nickel plating and acidic gold water) can be used to complete. Of course, other potions are needed. The ENIG surface treatment process is generally to first make chemical nickel deposition on the copper pad, and control the thickness of the nickel layer by controlling the time and temperature. Then use the fresh nickel activity just after the deposition, immerse the nickel pad in acidic gold water. Through the chemical displacement reaction displaces gold from the solution to the pad surface, and part of the nickel on the surface dissolves into the gold water. The chemical substitution reaction replaces the gold from the solution to the pad surface, and part of the nickel on the surface is dissolved in the gold water. The replaced gold will gradually cover the nickel layer until the nickel layer is completely covered. The replacement reaction will automatically stop, and the process can be completed after cleaning the dirt on the pad surface. At this time, the gold-plated layer is often only about 0.05um thick or thinner, so the ENIG process is very easy to control and the cost is relatively low (compared to electroplated nickel gold).

Obviously, this thin gold layer on the surface can only play a role in the oxidation protection of the nickel layer. Once the gold layer is not enough to protect the nickel layer, causing nickel to contact with the air to corrode and oxidize or be eroded by gold water transition, it will form the so-called black pad phenomenon, and at this time the surface of the pad is still shiny gold with the naked eye, it is generally difficult to judge whether there is a problem by visual inspection. Therefore, it is necessary to strengthen the quality inspection of ENIG surface-treated PCB before the assembly process.

The Formation and Harm of Black Pad

The quality of the nickel layer mainly depends on the formulation of the nickel plating solution and the temperature control during the chemical deposition. Of course, it also has a certain relationship with the process of acid gold water treatment. The process of electroless nickel plating is to obtain a plating layer through the autocatalytic reaction of hypophosphite and nickel salt on the surface of the pad, and the plating layer will contain a certain amount of “phosphorus (P)”. Many studies have shown that the normal ratio of phosphorus (P) in the plating layer should be between 7% and 10%. If the formulation of the plating solution cannot be immediately maintained or the temperature is out of control, the phosphorus content will deviate from this normal range. When the phosphorus content is low, the coating will be very easy corrosion, this corrosion first comes from acidic gold water erosion, when the phosphorus content is too high, the hardness of the formed coating will increase significantly, resulting in a decrease in the weldability, and will also seriously affect the formation of reliable solder joints. If the phosphorous content in the nickel plating is low, and the chemical substitution reaction is not properly treated during gold plating, if a large number of cracked gold plating is obtained, the acidic gold water will certainly not be easily removed in the subsequent cleaning process, which will cause the corrosion of the nickel plating exposed in the air to accelerate and eventually form the black pad.

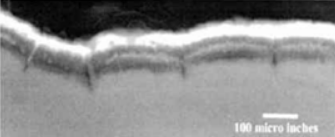

The typical black pad photo is shown in Figure 1, and the cross section of the black pad is shown in Figure 2. From the photo of the cross section, it can be seen that there are typical longitudinal cracks, which are typical characteristics of black nickel.

When black nickel is generated, the gold coating on the surface of ENIG will not have obvious discoloration, which is easy to give the illusion that the surface treatment of the pad is still good. When this solder pad is soldered at high temperature, the gold as a solderability protective layer will quickly dissolve into the solder paste, and the nickel that has been corroded and oxidized cannot form IMC with molten tin, resulting in a serious decline in the reliability of the solder joint. As long as it is slightly affected by external forces, cracking occurs.

Formation and harm of phosphorus-rich layer

ENIG surface-treated solder pads, in the welding process, the actual alloy with the solder paste is the “nickel” in ENIG, the typical intermetallic compound (IMC) alloy is Ni3Sn4, and the phosphorus in the nickel plating dose not participate in the metal chemical reaction, but in the nickel layer, phosphorus occupies a certain proportion and is evenly distributed. In this way, after the nickel participates in alloying, the local excess phosphorus will be enriched and concentrated at the edge of the alloy layer to form rich phosphorus layer, if the phosphorus-rich layer is too thick, its strength will be greatly reduced. When the solder joint is subjected to external stress, it must be destroyed first from the most vulnerable link, and the phosphorus-rich layer may be the weakest link to be destroyed first. The reliability of solder joints must be obviously affected.

Especially in the high-heat lead-free process, if the process is poorly controlled, the intermetallic compound is often thicker, resulting in more surplus phosphorus, the more the phosphorus-rich layer becomes more obvious, and the reliability of the solder joint is at risk. A typical phosphorus-rich layer is shown in the black zone between the intermetallic compound and the nickel plating layer in . This black band-shaped region can be analyzed by an energy spectrum analyzer (EDS) to confirm that it contains extremely high levels of phosphorus. A large number of failure cases have proved that the existence of the phosphorus-rich layer is a major cause of solder joint cracking failure.

Prevention and Control of Black Nickel and Phosphorus-rich Layer

Although the formation of black nickel and the appearance of phosphorus-rich layers are highly concealed, it may be difficult to detect and prevent by general means. But when we understand the causes, we can find effective methods of prevention and control.

For the formation of black nickel, the manufacturing stage is mainly to do the maintenance of the plating solution and the control of the process temperature, so that the nickel-phosphorus ratio in the plating layer is in the best state. Acidic gold water also needs to be well maintained, and should be adjusted in time when its corrosivity is too strong.

For users, the best method is to use a scanning electron microscope (SEM) to make a microscopic surface observation of the surface treatment of the pad, mainly to check whether there is a crack in the gold plating layer, and use EDS to analyze whether the proportion of phosphorus in the nickel plating layer is within the normal range.

Secondly, you can choose a typical pad to be manually welded and measure the push-pull strength of its solder joints. When it is found that the push-pull strength is abnormally small, there may be black nickel.

The last method is to perform an acid gas corrosion test on the ENIG sample. If powder or discoloration is found on the surface of the ENIG sample, it means that the gold plating on the pad is cracked, which means the possibility of existing the black pad.

Among these methods, the most convenient and fast should be the second method, which is simple and easy. With these measures, problems can be discovered early before the ENIG circuit board is used, to avoid the generation of a large number of circuit board components with reliability problems, and thus to minimize losses.

For the production of phosphorus-rich layer, when the proportion of phosphorus-nickel in the nickel plating layer is appropriate, the welding process is mainly controlled, the welding time and the welding temperature are controlled, and the thickness of the intermetallic compound is controlled at the optimal 1 to 2 microns (um), when too thick intermetallic compounds (IMC) are produced, they must also be enriched with an excessively thick phosphorous-rich layer.

Comments

Post a Comment