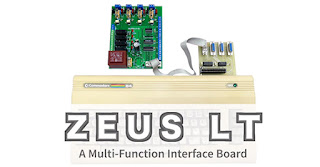

Zeus LT — -A multi-function interface board for the Commodore 64

Amigastyle, who is a big fan of Commodore 64 computers, designs Zeus LT Board, a multi-function interface board for Commodore 64. Plugging the Zion adapter into the Zeus LT, you could open up a world of more possibilities: Control smart home devices; Design, test, and debug Internet-of-Things (IoT) solutions Develop retro games Learn or teach basic electronics and basic programming Zion is a simple but essential interface between your Commodore 64 and your Zeus LT. It comes in two versions — -Zion LT and Zion F. The Zion LT includes the exposed made edge connector for the C64 expansion port, reset button and one 15-pin D-sub connectors for Zeus LT boards. The Zion F has the same function as the LT. It includes exposed male edge connector for C64 expansion port, reset button, four 15-pin D-sub connectors for Zeus LT boards and female pass-through cartridge slot(for when Zeus LT is not in use). The Zeus LT adds external I/O support to Commodore 64. It includes a single-15-pin D-sub conne